Industrial Robot Glass Cutting Station

Advanced Simulation for Efficient, High-Precision Flexible Production

Industrial-Scale Manufacturing for Glassware

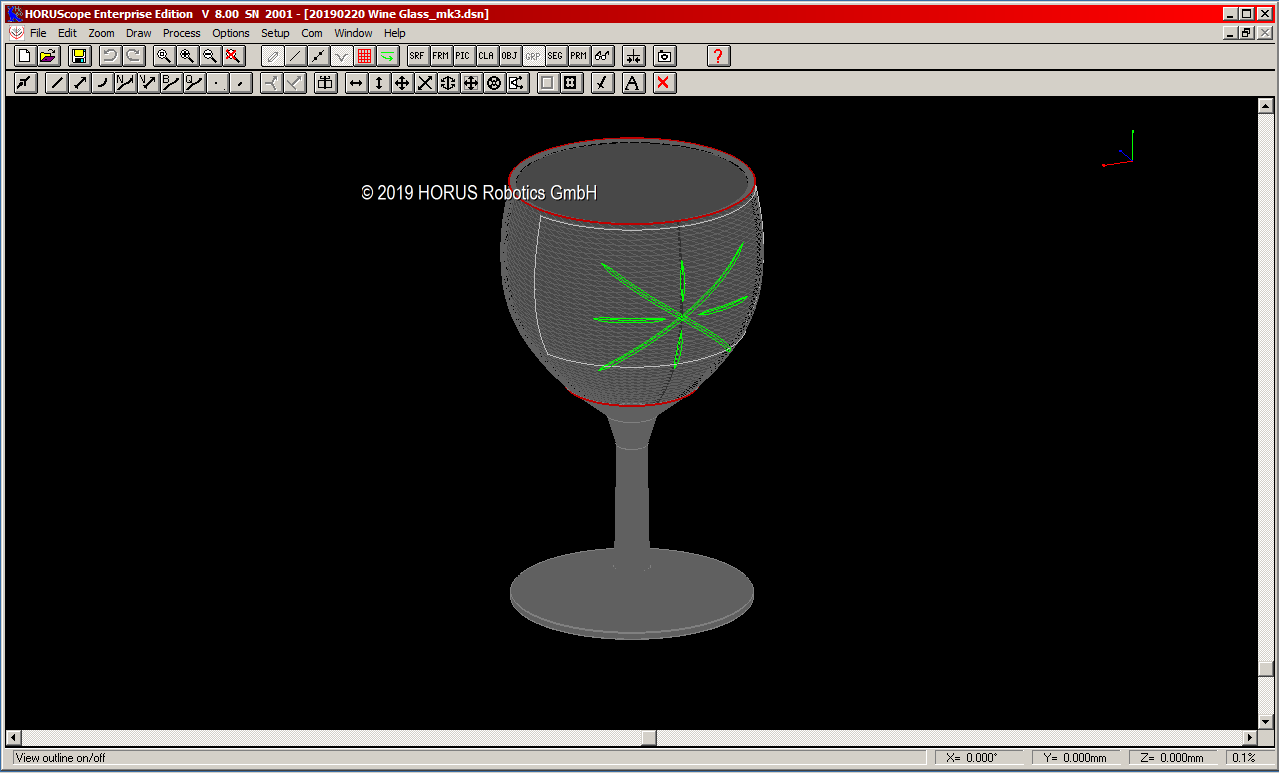

Our robot cutting technology is engineered for manufacturers where accuracy and material efficiency are paramount. By utilizing the HORUScope V8.0 simulation environment, we significantly reduce the traditional setup phase. This allows for highly efficient single-piece and small batch production.

If the browser is unable to play the video, please download it manually here

Individually configurable

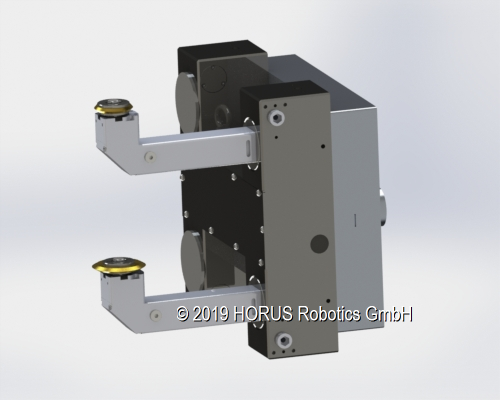

Large freedom for stems

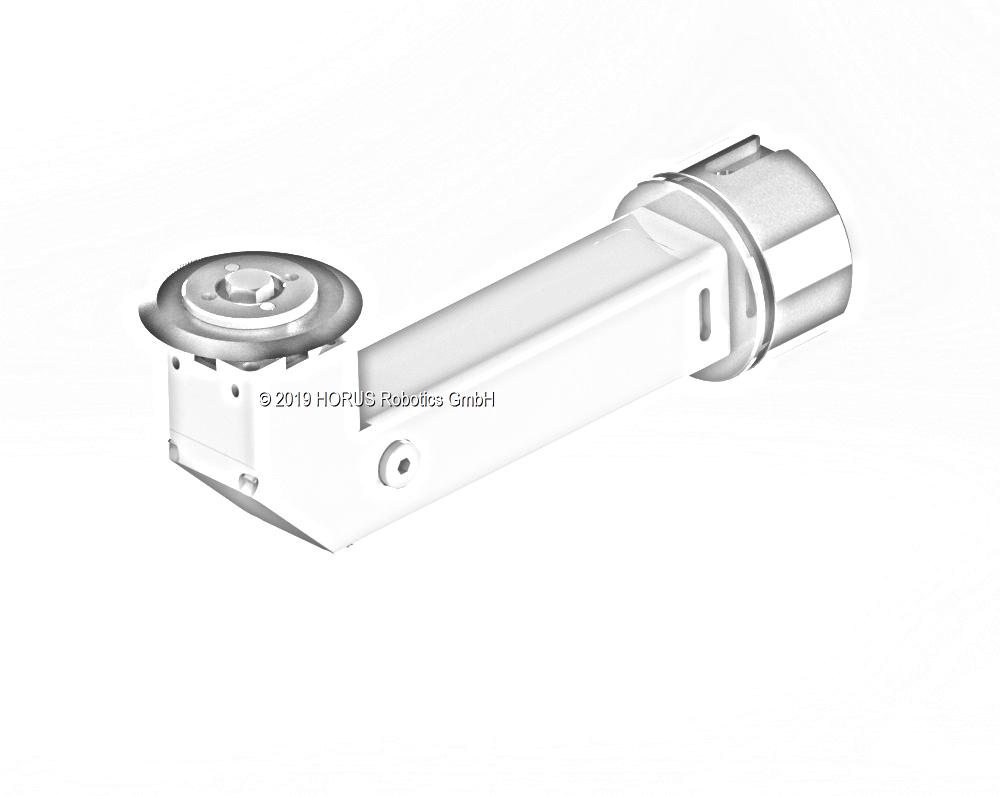

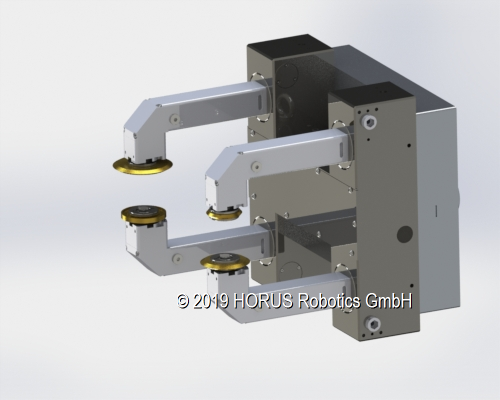

Each cutting arm can be mounted in one of two orientations

Cutting between wheels

The new generation of decor cutting machines

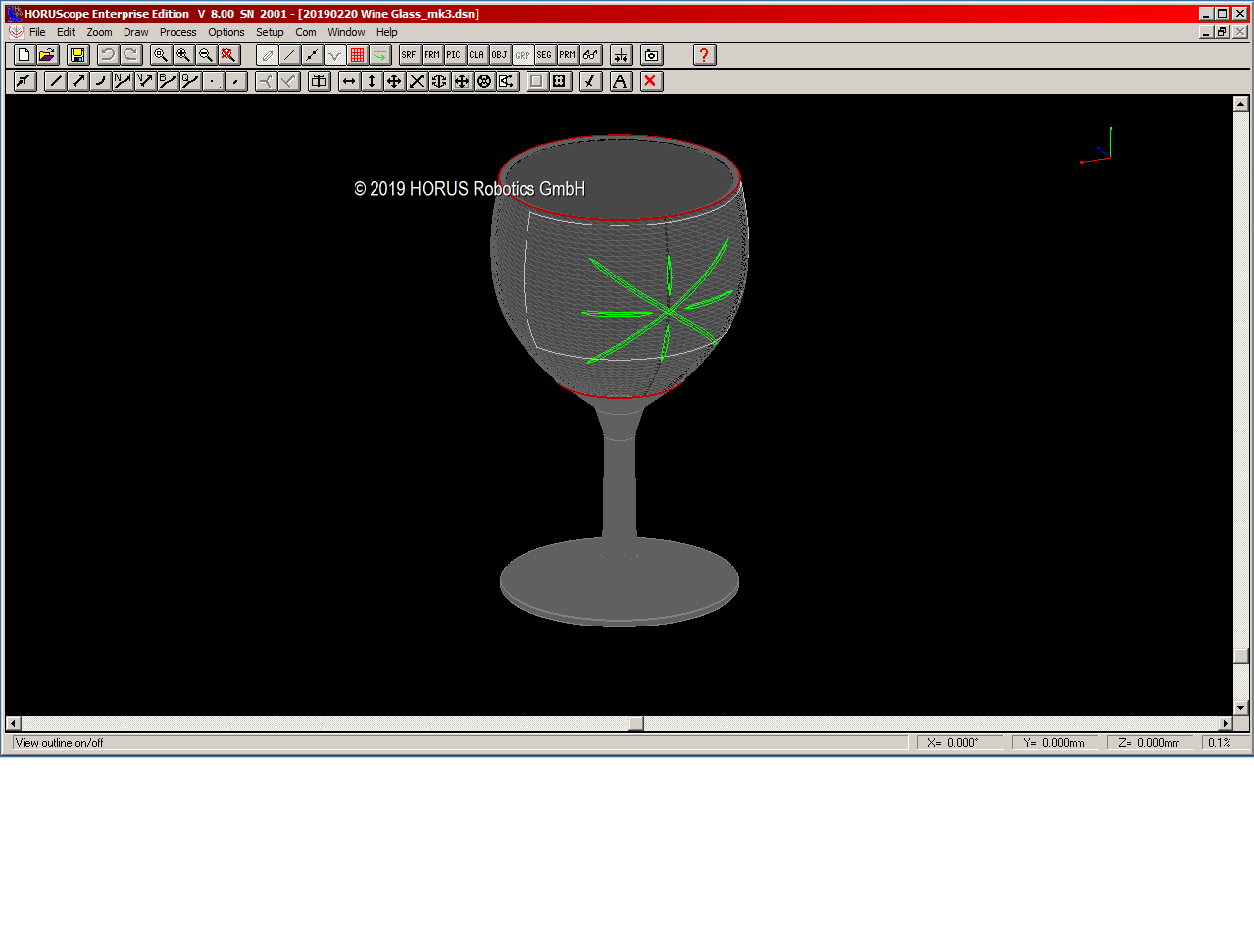

HORUScope 8.0 CAD CAM Software for Glass Decor Cutting

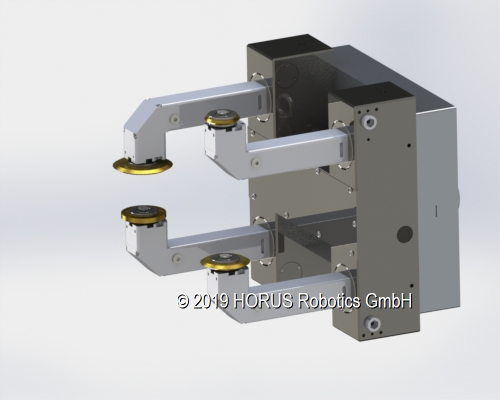

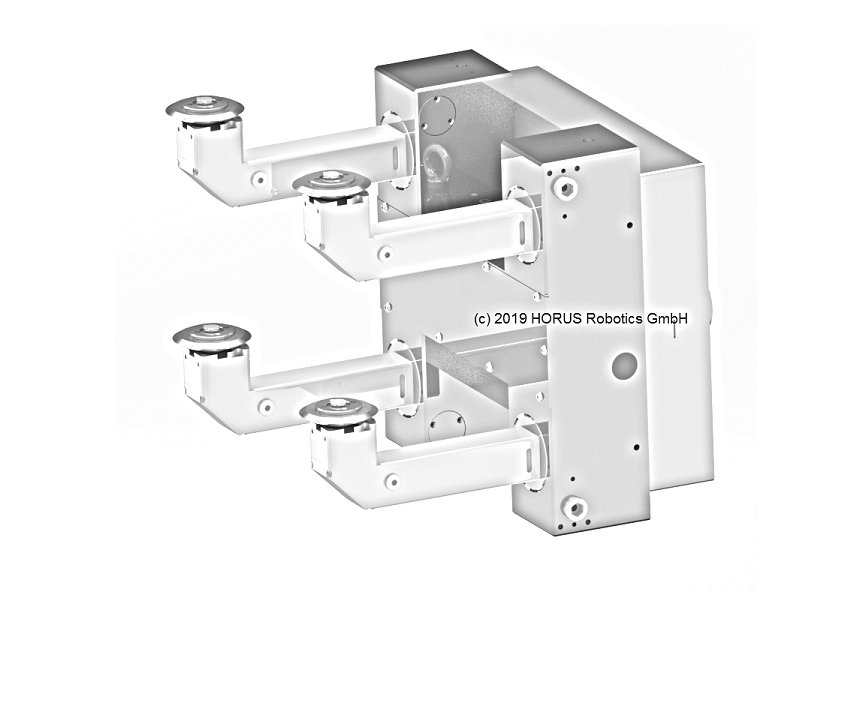

HORUS Robot Cutting Station with 4 Diamond Grinding Wheels

Special Features

Servo Controlled Cutting Force

- Real time cutting force measurement

- Precise surface following

- Compensation for geometrical tolerances in production batches

- Improved quality at cut crossing points

Automatic Loading and Unloading

From an external feed

Processing with Up to 4 Cutting Wheels

On easily mounted arms

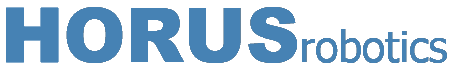

Cutting Arm Concept

Introduction of the cutting arm concept

Decor Cutting – From Design to Finished Glass: An Integrated System

The Robot Cutting Station is controlled by the "HORUS Robot Master" firmware. Cutting data is generated using the HORUScope V8.0 CAD/CAM system.

Designs generated by previous versions of HORUScope and also by Wincut Pro can be imported into HORUScope V8.0.

Designs can be drawn directly on the surface of the glass using HORUScope V8.0